BRIEF

Big Data in Manufacturing

Imagine doing data entry for months. Imagine flipping through pages of complicated process and instrumentation diagrams (see below) on the hunt for tiny alphanumeric codes. Imagine that, even with your chemical engineering degree, you don’t recognize these codes because they are different for each customer; their descriptions are written in Arabic, or Korean, or Spanish, or Italian.

Setting up a plant to send measured data from Honeywell sensors for optimization of petrochemical processes could take up to 6 months. I was lead designer on transforming this Excel-based monthslong struggle into an hourslong task with smart algorithmic datapoint matching. This endeavor was called Tag Mapping.

Outline

- Timeline

August 2019 – June 2020 - Employer

Honeywell / Atlanta, GA

Responsibilities / Tools

- User Research / Engineering Degree, MS Teams

- Information Architecture / Design Sprints

- Design System Creation / Workshops, Sketch

- Hifi Mockups / Sketch, Abstract

- Hifi Prototypes / Sketch, InVision

PROCESS & INSTRUMENTATION DIAGRAM

Given a combined P&ID from a customer, Honeywell's chemical engineers would have to play part translator and part cryptographer. The above P&ID is from a Korean plant.

With 1000s upon 1000s of customer datapoints to map to Honeywell tag names, chemical engineers would start with a blank Excel template. In the Excel screenshot below, the green columns are dropdowns whereas the red columns require manual entry of the customer's alphanumeric codes, or tag names.

Honeywell’s chemical engineers would have to enter customer tag names found in the P&ID one-by-one, mapping each to its Honeywell counterpart. This would eventually create a digital twin of the entire plant, including its miles of pipes, compressors, heaters, pumps, and other equipment, within Honeywell’s database.

MANUAL DATA ENTRY for 1000s of DATAPOINTS

Once the Excel templates were filled properly, chemical engineers would then upload them into Honeywell's Model Builder web app. If any tag was mapped incorrecly due to a stray character or typo, it and all of its 100s of connected attributes would not render.

To be frank, this process was awful. It was extremely time-consuming, tedious, error-prone, and time-consuming. Because chemical engineers spent months on this setup process, they had little to no time to lend their optimization expertise to customers. What they were actually hired for, none had the time to do.

As soon as I was tasked with this initiative, I and my design team's research manager interviewed 17 colleagues and users in chemical engineering, product, software development, and data science roles. We received countless demos and current process feedback along with walkthroughs of an ideal workflow. Next, we designers conducted workshops with data scientists and developers all over Honeywell worldwide to make this mayhem an automated operation using custom algorithms.

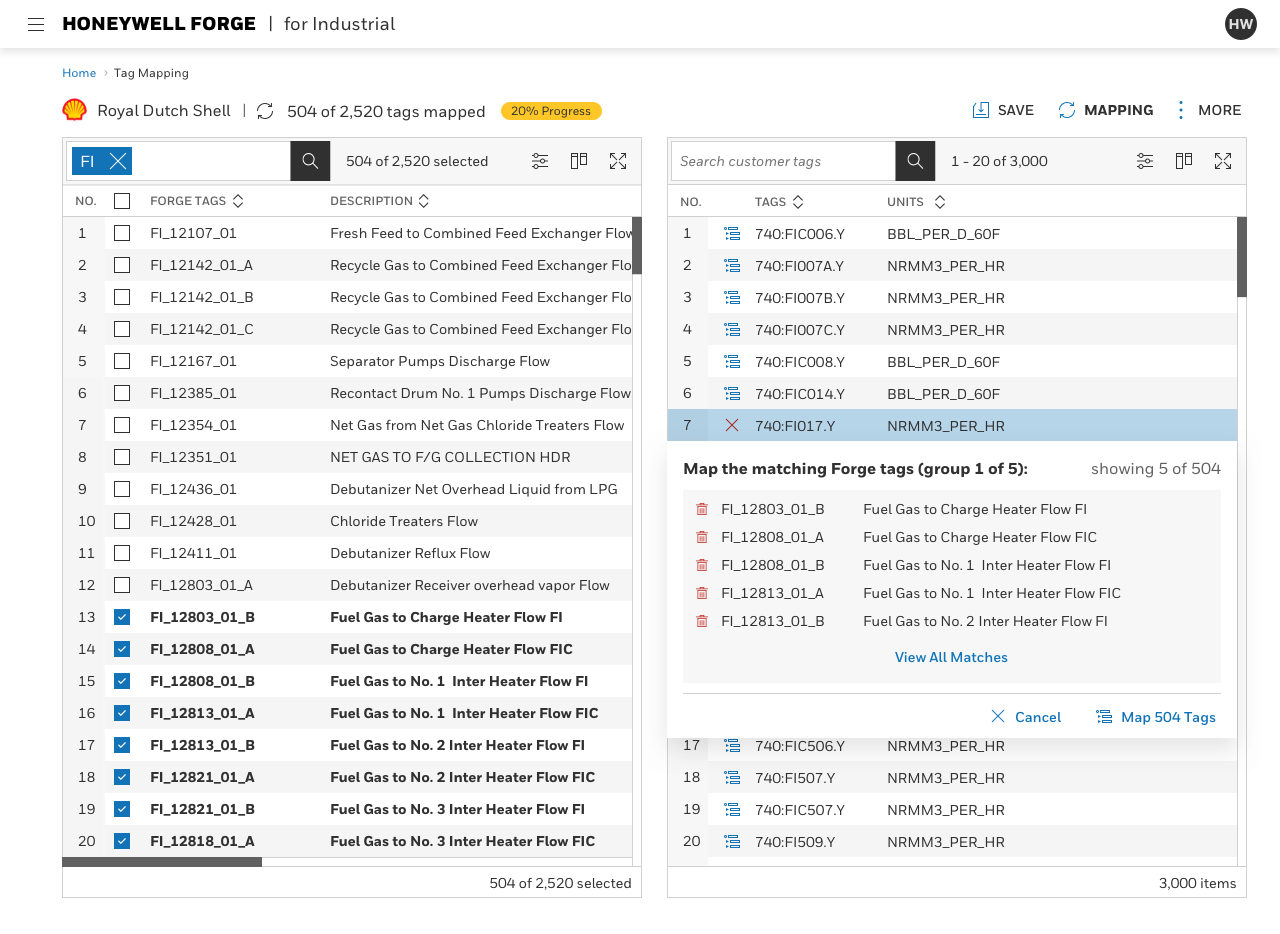

START and END in MODEL BUILDER INSTEAD of MULTIPLE APPLICATIONS

We came up with a process where chemical engineers would start Tag Mapping in Honeywell's Model Builder web app instead of Excel.

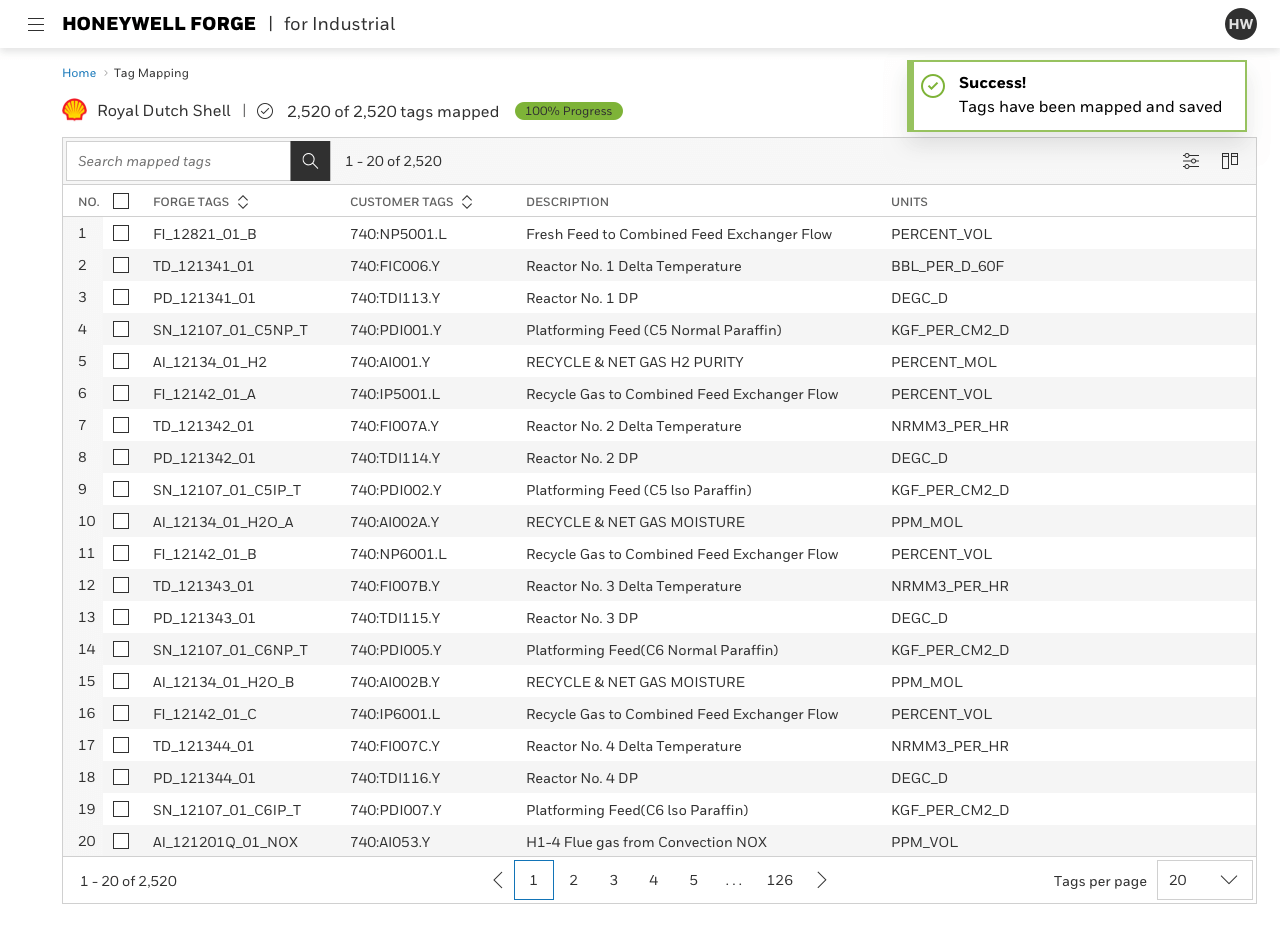

Raw tag names and instrument data from the customer would be uploaded, then smartly categorized based on the instrument type. Using this method, chemical engineers would just have to confirm smart suggestions from the system. Thanks to the algorithm, tags could be mapped 100s at a time instead of one-by-one. No manual data entry required.

MAP 100s of TAGS in GROUPS INSTEAD OF ONE-by-ONE

FINISH in ONE WORKDAY INSTEAD of MONTHS LATER

01 / Challenges

So I'm a mechanical engineer, not a chemical engineer. That fact was never more evident until I joined Honeywell. Translating chem speak into layman's English was a skill I had to master immediately.

02 / Wins

This design initiative saved everyone on the Honeywell and customer sides so much time. It freed up chemical engineers to offer their expertise in saving plants money and eliminating harmful waste.

03 / Lessons

Big data should be crunched by machines, not people. This project reminded me of why I pivoted to design from engineering – and would make the same decision today.