BRIEF

Green Engineering

Low Temperature Combustion with Reduced PM and NOx Emissions, Achieved by n-Butanol in-Port Injected in an Omnivorous Diesel Engine

Diesel engines have a bad rep in the US as being dirty, loud, and reserved only for large work trucks. For this project, we sought to dispel the negative stereotypes. A Cummins diesel engine was converted to run on biodiesel and fitted with an exhaust gas recirculation (EGR) system. For fuel, the engine used cottonseed oil, donated from local Georgia farmers.

EPA Press Release launchOutline

- Timeline

August 2012 – May 2013 - Client

U.S. Environmental Protection Agency

Details

- Exhaust Flow Calibration

- Capstone Project for Engine Testing Course

- $90k EPA Grant for People, Prosperity & the Planet

GSU EXHIBIT in DC

GSU ENGINES and FUEL TESTING LAB

COMPONENTS DIAGRAM

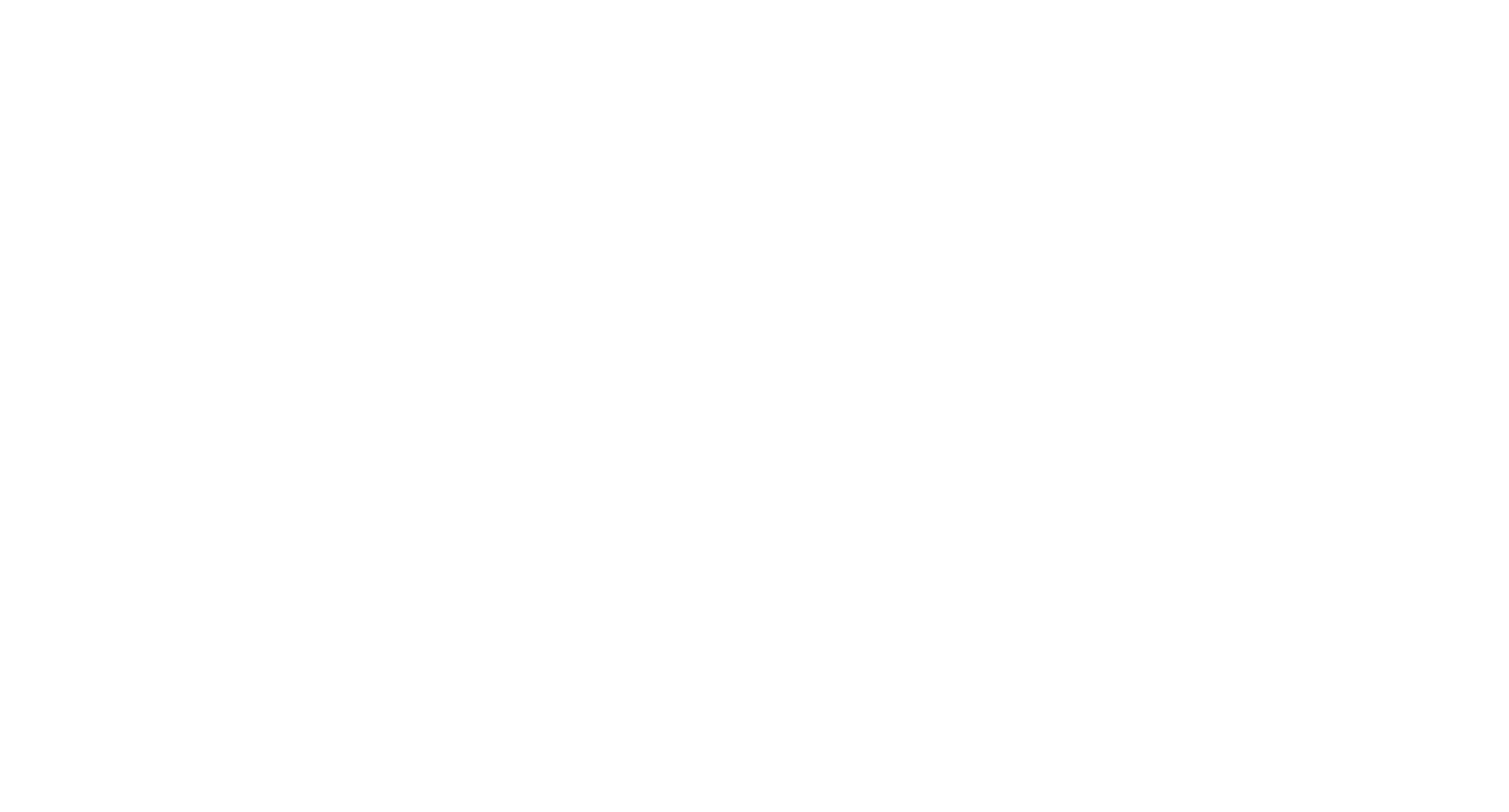

An electric mini vehicle (see Figure 2) was used to pull and transport the 700lb biodiesel engine.

To reduce output of poisonous NOx gases that form at high temperatures, the ignition of the fuel mix in the combustion chamber was delayed, thus lowering the combustion's temperature. Additionally, since soot is made up of burnt, wasted fuel, lowering the combustion temperature reduced the creation of this waste.

The EGR recycled the unspent fuel, reintroducing it to the combustion chamber. The recycling of these emissions dramatically reduced the soot and NOx production by over 50%. Unfortunately, this 'choking' resulted in horsepower loss. Phase II of the grant award was put toward the research, design and installation of a supercharger to regain the lost power.

PROUD ENGINEERS